4DIFY is revolutionizing the way homes are built by combining exclusive 3D printing technology with sustainable construction practices. From the first layer of printed concrete to turnkey homes, we’re accelerating timelines, cutting costs, and building with resilience—delivering smarter, stronger, and greener housing where it’s needed most.

About Us

4DIFY is a next-generation construction company redefining how homes are built. With exclusive rights to SQ4D’s groundbreaking 3D printing technology in California, we’re leading the shift toward faster, more sustainable, and more resilient housing. Our mission is simple: build better—smarter, stronger, and greener. By automating the construction process with robotic precision and reducing material waste, we’re cutting build times by up to 75% and significantly lowering costs—while increasing structural integrity, fire resistance, and seismic performance.

Whether we’re printing homes for wildfire recovery or powering the next wave of affordable housing, 4DIFY is committed to solving California’s most urgent housing challenges—one layer at a time.

4Dify presents a compelling investment opportunity by combining innovative 3D printing construction services with profitable equipment sales commissions and royalty income. Our adjusted business model reduces capital requirements while maintaining significant time and cost advantages.

With exclusive rights in California and a clear growth strategy—including an attractive and flexible investor return structure—we are poised for substantial success and robust financial returns.

What We Bring

Glass Fiber Reinforced Rebar

Sustainable Mix Designs

Distribution of Materials

Sustainability Driven

Design | Engineering as a Service

Proprietary Wall Designs

Engineering, Modeling, Estimating

Training program and facility in partnership with academia that produces 3DCP workers.

Our homes have substantial heating and cooling savings, with efficiency up to 50%.

Fire, flood, wind, and pest resistance can lower insurance costs-one NY home saved 47%.

Concrete is resistant to pests like termites, which cannot nest in or chew through it.

Our homes are constructed with Class 2 fire-resistant materials, which have low thermal conductivity and high heat capacity, enabling them to absorb heat and insulate structural elements. These materials maintain structural integrity at elevated temperatures, providing an effective fire barrier.

Concrete is naturally water-resistant and mold-resistant.

Our homes are reinforced with steel rebar, mesh, & structural monolithic beams to enhance strength & seismic flexibility, incorporating high-rise commercial-grade applications into residential homes.

Our Story

Kaizen Way

Southcliff Dr.

Our Clients

Join our roster of satisfied clients and experience the exceptional results and service that have earned us the trust of industry leaders worldwide.

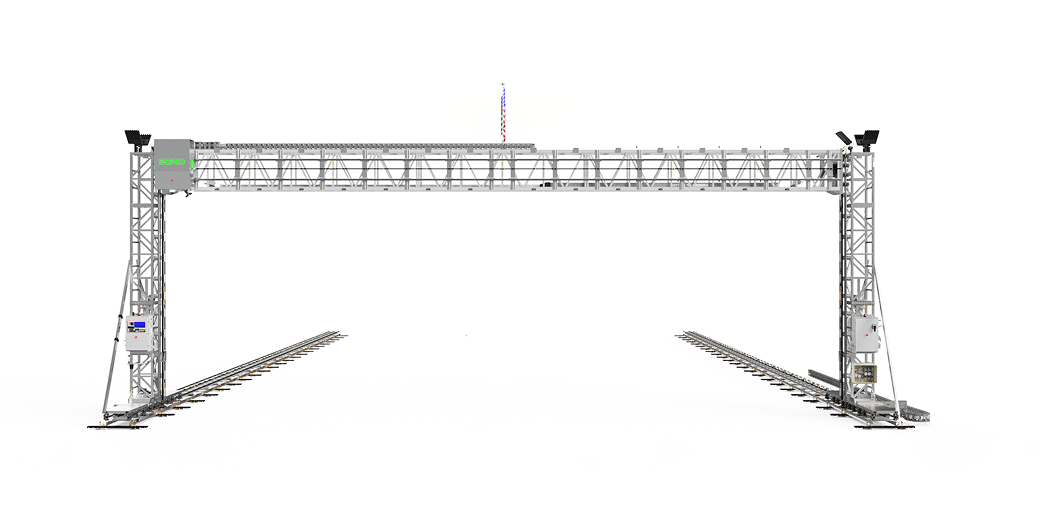

4Dify has built a ruggedized gantry-style 3D printer capable of building full-sized commercial and residential structures. ARCS was designed to outlast mother nature and all job sites. Our technology is not limited to buildings – if you can dream it, you can build it.

Printing in hot weather makes concrete more prone to cracking given that it dries out without fully curing. To combat this, 4Dify can use colder water within the concrete mix as well as moisturizing after layers have been printed. With the proper precautions, 4Dify can print concrete no matter the temperature.

Plumbing installation begins as it normally would by excavating, installing plumbing in the ground, and backfilling with dirt. Next, after the footing and foundation have been completed, the slab is printed around the plumbing stub-ups. After the walls are printed, panels are created in order to provide access areas in the event that plumbing and wiring issues need to be resolved. On top of this, servicing from above is possible. Further on top of this, insulation remains pliable so taking out and replacing is not an issue.

When it comes to printing the footing of a structure, we can print to any depth required of a structure. The only thing that would need to be adjusted with the printer is the length of the nozzle extruding the concrete.

3D printing allows for the customization of many aspects of a home. One important aspect is the insulation and corresponding R value, or the measure of how well the wall resists the conductive flow of heat. 3D printing custom walls allows for changing wall width at no additional cost, which allows for more insulation and higher R values. Unlike traditional stick built construction where wall widths would be increased using larger and more expensive lumber (i.e. 2×4 vs 2×6 vs 2×12 etc.), the 3D printed beads can just be placed at different distances apart, thus increasing the energy efficiency in the home.

Client

Testimonials

Futurism

Testimonials

CNBC